Rambling repair post...

Moderators: Tim Bosma, Tom Elsen

- SailingUphill

- Posts: 204

- Joined: Fri Aug 17, 2012 1:52 pm

Re: Rambling repair post...

Similar to this... and yes the polyester stuff is pretty toxic too.. but then so is this crap.

http://www.defender.com/product.jsp?pat ... 1&id=18651

http://www.defender.com/product.jsp?pat ... 1&id=18651

Presently hull 399, "Ragtime" Blackwater Yacht Racing, Smith Mountain Lake, VA

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Re: Rambling repair post...

That's Polyester resin. The "Laminating Resin" differs from finishing resin in that the surface stays tacky even when cured so that the next coat will bond. Finishing Resin has paraffin in it which floats to the surface and seals that off from the air, allowing a tack free cure. But..... It must be sanded and cleaned really well to insure a bond with the next coat(s).

- SailingUphill

- Posts: 204

- Joined: Fri Aug 17, 2012 1:52 pm

Re: Rambling repair post...

That explains the tacky build-up then... There is a fine line between cured enough, and not... and I'm learning the exact amount of time between layers I need... and it's tricky cause it's really too damned cold to do this... It isn't when I apply it of course, but once I leave the barn, it gets cold quickly afterward.

Presently hull 399, "Ragtime" Blackwater Yacht Racing, Smith Mountain Lake, VA

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Re: Rambling repair post...

If you can find some styrene somewhere, you can shave some paraffin into it to have a cured surface on your last coat. Saves LOTS of time, acetone/MEK and brain cells not having to get rid of the sticky residue before grinding/sanding. Then again, if you have a good glass repair shop close by you can simply buy the wax add.

It's not the best thing to work with that stuff when it's cold. Every resin (even epoxies) has a certain exotherm temperture that should be reached for that resin to reach maximum physical properties. If that doesn't happen, the resin still looks to be "hard" but is never as strong as it should have, could have been. I realize that one has to make hay while the sun shines, but to borrow another old adage: there's no free lunch!

It's not the best thing to work with that stuff when it's cold. Every resin (even epoxies) has a certain exotherm temperture that should be reached for that resin to reach maximum physical properties. If that doesn't happen, the resin still looks to be "hard" but is never as strong as it should have, could have been. I realize that one has to make hay while the sun shines, but to borrow another old adage: there's no free lunch!

- SailingUphill

- Posts: 204

- Joined: Fri Aug 17, 2012 1:52 pm

Re: Rambling repair post...

Interesting results epoxy versus laminating resin (poly) with gelcoat bond.

The prep and the testing process.

The results...

The prep and the testing process.

The results...

Presently hull 399, "Ragtime" Blackwater Yacht Racing, Smith Mountain Lake, VA

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

- SailingUphill

- Posts: 204

- Joined: Fri Aug 17, 2012 1:52 pm

Re: Rambling repair post...

Each forum links youtubes differently...

https://www.youtube.com/watch?v=GwS4YgoGFm8

https://www.youtube.com/watch?v=kHAb...em-subs_digest

Results were quite positive.

https://www.youtube.com/watch?v=GwS4YgoGFm8

https://www.youtube.com/watch?v=kHAb...em-subs_digest

Results were quite positive.

Presently hull 399, "Ragtime" Blackwater Yacht Racing, Smith Mountain Lake, VA

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Re: Rambling repair post...

I never could get the second link to work.

Just some personal history: in well over 44 years of working with composits, including Polyester and Epoxy, I have yet to ever see gelcoat cure when applied over epoxy! I have a good friend who's been working with all of this far longer than me and on many more, and larger projects, rebuilds, etc. He has had exactly the same results.

I know that WEST System says this works, but not for either of us, in any temperature, humidity or location.

Similarly, but it oposite steps: I once made a mold of a Laser mast step and surrounding area to build new steps and then instal in the wrecked boats. I used Polyester gelcoat in the mold and allowed it to cure well, followed by a laminate using WEST epoxy. When I pulled the completed mold from the plug, the gelcoat popped off of the laminate anywhere there was a sharp radius, as where the deck turns down into the hole where the mast steps.

Fool me once............

Never again!

Just some personal history: in well over 44 years of working with composits, including Polyester and Epoxy, I have yet to ever see gelcoat cure when applied over epoxy! I have a good friend who's been working with all of this far longer than me and on many more, and larger projects, rebuilds, etc. He has had exactly the same results.

I know that WEST System says this works, but not for either of us, in any temperature, humidity or location.

Similarly, but it oposite steps: I once made a mold of a Laser mast step and surrounding area to build new steps and then instal in the wrecked boats. I used Polyester gelcoat in the mold and allowed it to cure well, followed by a laminate using WEST epoxy. When I pulled the completed mold from the plug, the gelcoat popped off of the laminate anywhere there was a sharp radius, as where the deck turns down into the hole where the mast steps.

Fool me once............

Never again!

- SailingUphill

- Posts: 204

- Joined: Fri Aug 17, 2012 1:52 pm

Re: Rambling repair post...

I find it interesting, but the link is now broken... the results were pretty telling... it would appear that West 507 was better than 506 or 508... but they all held pretty well, surprisingly so.

Regardless.... I had always heard you can do epoxy over resin, but not the other way around.. which means no gelcoat over epoxy... So that was the way I was headed. But I've never actually tried any of it.

What was surprising was that I believe his name is Andy, said that he has never recommended gelcoat over epoxy... and felt like he should test it. So he created his own test to try it. There were some huge statements at the end of the video stating that West Systems did not sponsor the test, but rather encouraged he come up with his own... he also was trying to get his samples put into a tensile tester (much like we use at work)... to figure out the tensile strength of the mechanical bond... I WONDER if either A) his tests were disastrous under tensile or B) he pulled his video to add the results of those tests...

I've watched several of his video series, some several times to get as much info as I could out of them. Again this is all new to me.

Regardless.... I had always heard you can do epoxy over resin, but not the other way around.. which means no gelcoat over epoxy... So that was the way I was headed. But I've never actually tried any of it.

What was surprising was that I believe his name is Andy, said that he has never recommended gelcoat over epoxy... and felt like he should test it. So he created his own test to try it. There were some huge statements at the end of the video stating that West Systems did not sponsor the test, but rather encouraged he come up with his own... he also was trying to get his samples put into a tensile tester (much like we use at work)... to figure out the tensile strength of the mechanical bond... I WONDER if either A) his tests were disastrous under tensile or B) he pulled his video to add the results of those tests...

I've watched several of his video series, some several times to get as much info as I could out of them. Again this is all new to me.

Presently hull 399, "Ragtime" Blackwater Yacht Racing, Smith Mountain Lake, VA

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Re: Rambling repair post...

You can bet your sweet bippee that WEST system would do everything in their power to keep anything negative about their products or recommendations from going public, ESPECIALLY on youtube!!!! Just like Hobie: the only reason that they still have such a huge market share is because they were the first out of the bag, and continue to spend a small fortune in convincing people they are still the best. ANY epoxy formulation which develops an amine blush when curing is ancient history in my book!

- SailingUphill

- Posts: 204

- Joined: Fri Aug 17, 2012 1:52 pm

Re: Rambling repair post...

Finally got some time to work on the boat again today... spent about 5 hours or so... whole house has just gone through a bout with the flu, despite us all having had the shot... so I lost 2 weeks thanks to that....

Listening to the my bluetooth from my phone, installed an FM antenna.... wired out power to the VHF, and the Electronics.

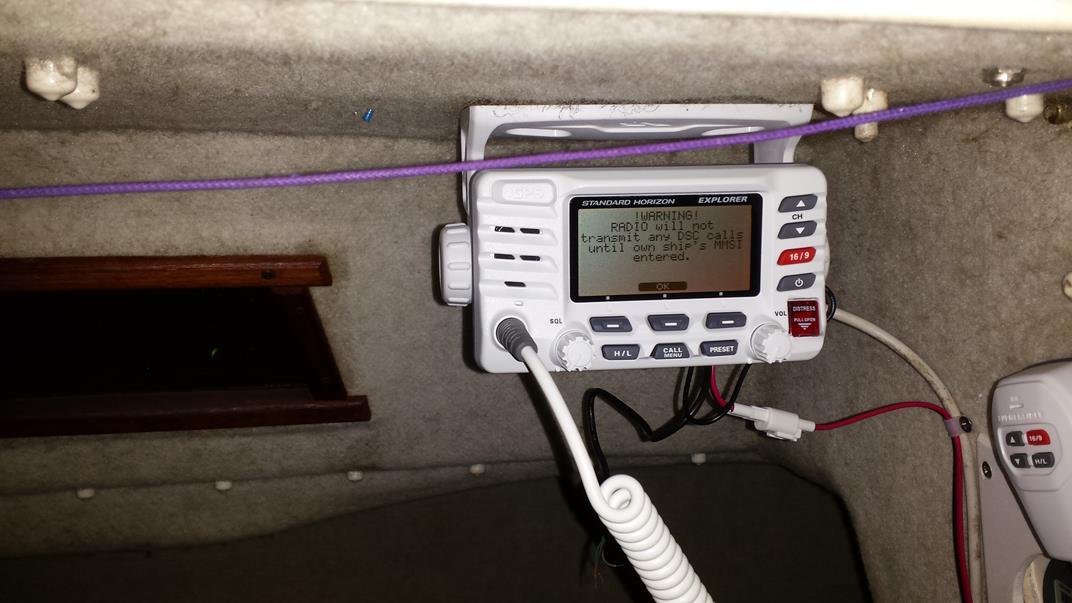

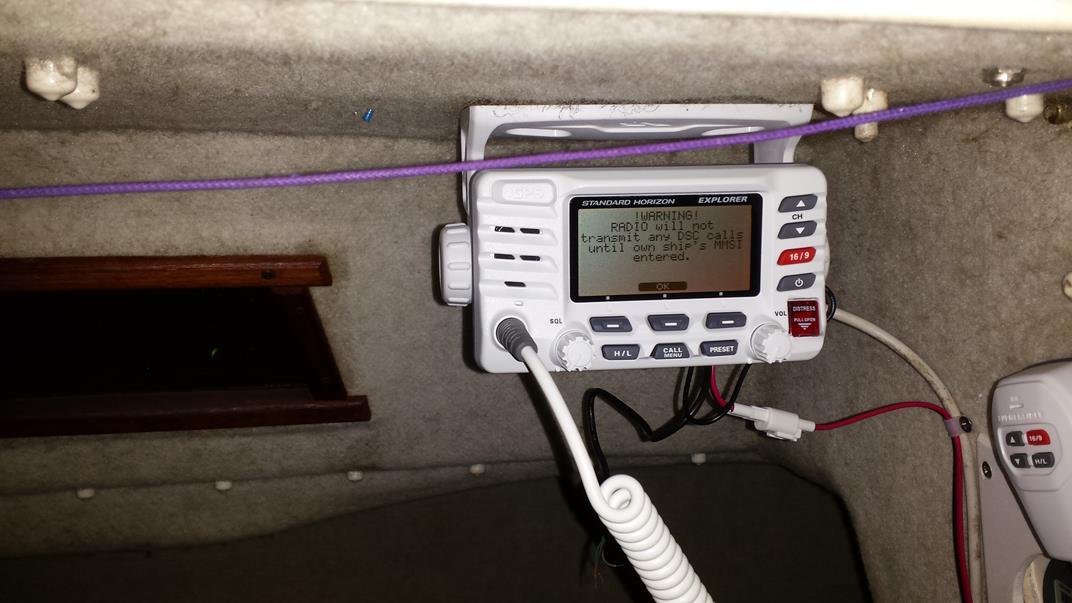

VHF all fired up... this is the prior location of the old (non-functional) VHF... the display was gone, and no transmit or receive, so it was time for new.

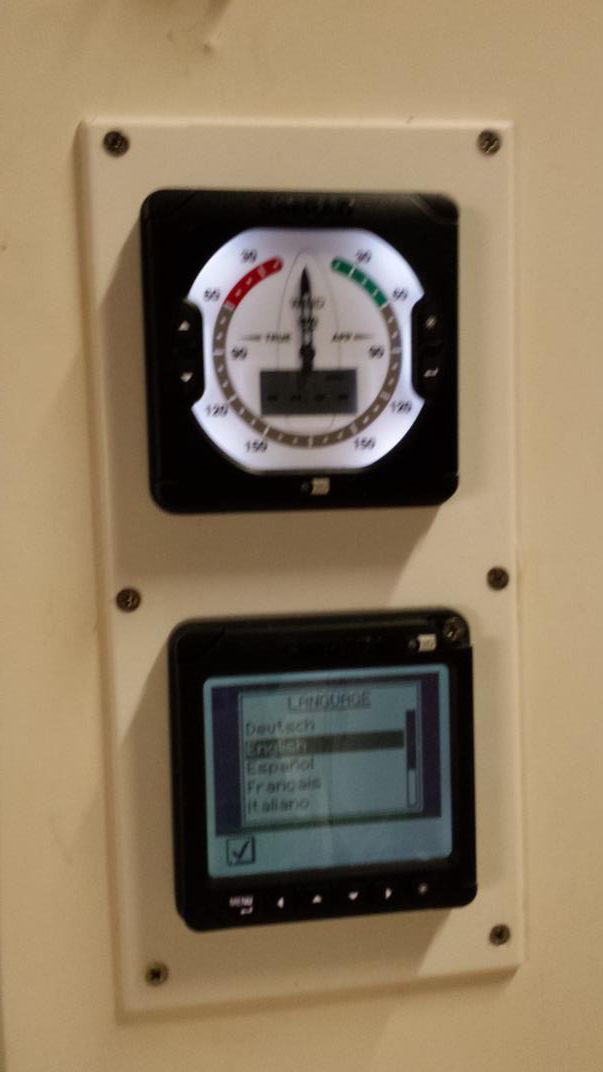

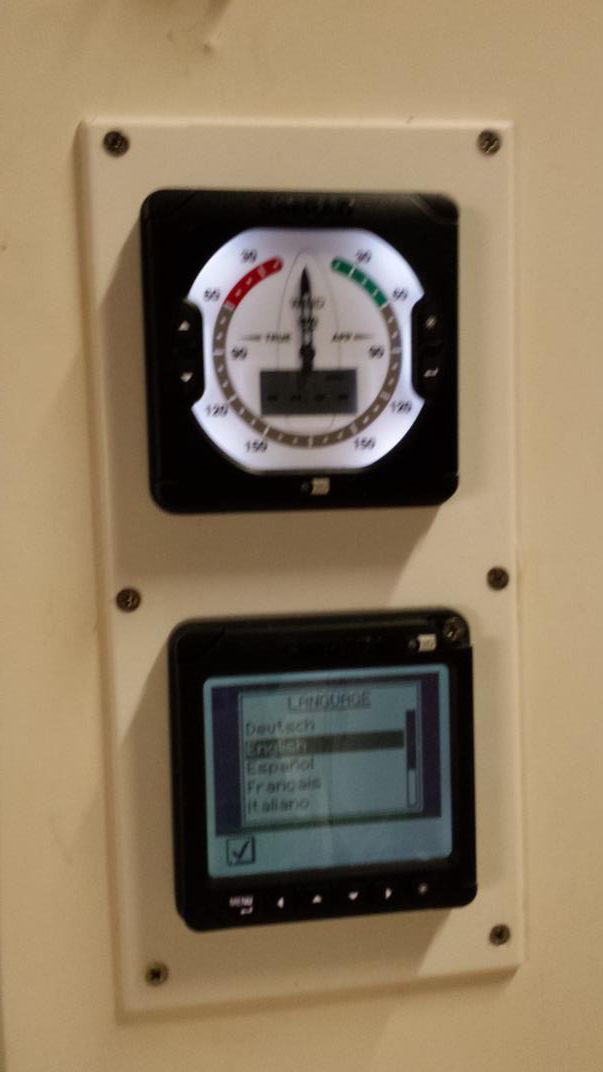

Proof I got power to the electronics too. I'm pretty happy it all worked, I did a lot of wiring before I got to this point... I still have no transducers installed, but one thing at a time.

Mast is now off too... Tons to do to the mast. All new halyards, run the simnet cable through, mount the mount for the wind transducer and perhaps paint the mast.

Honestly the mast had to come off first for me to move the boat forward about 6 feet or so, so I can put the rudder on. I want to make sure all my tolerances are correct, and everything works smoothly... if it all checks out, I am going to align and setup the tiller pilot. The tiller pilot is a smart tiller pilot, and uses a NMEA 2000/Simnet connector, and I intend to also put a 12V aux outlet in next to the TP plug. When that is done, the network/power wiring should be complete, and I can focus on the transducer, and mast, not to mention finish up the core work on the cockpit seat.

Listening to the my bluetooth from my phone, installed an FM antenna.... wired out power to the VHF, and the Electronics.

VHF all fired up... this is the prior location of the old (non-functional) VHF... the display was gone, and no transmit or receive, so it was time for new.

Proof I got power to the electronics too. I'm pretty happy it all worked, I did a lot of wiring before I got to this point... I still have no transducers installed, but one thing at a time.

Mast is now off too... Tons to do to the mast. All new halyards, run the simnet cable through, mount the mount for the wind transducer and perhaps paint the mast.

Honestly the mast had to come off first for me to move the boat forward about 6 feet or so, so I can put the rudder on. I want to make sure all my tolerances are correct, and everything works smoothly... if it all checks out, I am going to align and setup the tiller pilot. The tiller pilot is a smart tiller pilot, and uses a NMEA 2000/Simnet connector, and I intend to also put a 12V aux outlet in next to the TP plug. When that is done, the network/power wiring should be complete, and I can focus on the transducer, and mast, not to mention finish up the core work on the cockpit seat.

Presently hull 399, "Ragtime" Blackwater Yacht Racing, Smith Mountain Lake, VA

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

- SailingUphill

- Posts: 204

- Joined: Fri Aug 17, 2012 1:52 pm

Re: Rambling repair post...

Trying to figure out spacing for the tiller pilot.... using a crib board to check for level....

More holes in the boat.. magical 1 1/4" hole for the receptical.

Installed.

I went over several ways to mount the tiller pilot... I wanted to mount it on the seat, but it just wasn't happening, without adding a pedestal, and also a huge drop on the tiller side.. it didn't make sense. So on top it goes. It looks like I'm going to need about a 7 inch extension for it to reach correctly. Now to wire it all... Meanwhile I got all the other stuff wired up. Might need to rearrange the simnet blocks, but nicely the new tri-ducer fit perfectly into the old standard horizon through hull for the knot meter. Nice flush fit and I already know that through hull doesn't have any issues.

Here's a shot of the cluster up with me testing the tri-ducer.

I only tested temp, and speed, but it works... I also plugged in the wind transducer, and it also is working nicely... now to get it all organized.

More holes in the boat.. magical 1 1/4" hole for the receptical.

Installed.

I went over several ways to mount the tiller pilot... I wanted to mount it on the seat, but it just wasn't happening, without adding a pedestal, and also a huge drop on the tiller side.. it didn't make sense. So on top it goes. It looks like I'm going to need about a 7 inch extension for it to reach correctly. Now to wire it all... Meanwhile I got all the other stuff wired up. Might need to rearrange the simnet blocks, but nicely the new tri-ducer fit perfectly into the old standard horizon through hull for the knot meter. Nice flush fit and I already know that through hull doesn't have any issues.

Here's a shot of the cluster up with me testing the tri-ducer.

I only tested temp, and speed, but it works... I also plugged in the wind transducer, and it also is working nicely... now to get it all organized.

Presently hull 399, "Ragtime" Blackwater Yacht Racing, Smith Mountain Lake, VA

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

- SailingUphill

- Posts: 204

- Joined: Fri Aug 17, 2012 1:52 pm

Re: Rambling repair post...

Ok, I need some experts... This doesn't look good. This is my port spreader (after sanding). At first glance it looks like a surface crack, on a rolled weld. However, I may need some spreaders. Anyone have a source?

Presently hull 399, "Ragtime" Blackwater Yacht Racing, Smith Mountain Lake, VA

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

- SailingUphill

- Posts: 204

- Joined: Fri Aug 17, 2012 1:52 pm

Re: Rambling repair post...

Also are the holes supposed to be oblong liek this? It looks to be machined like this, not worn... but I thought I'd ask.

Mr. Fuzzycam reared it's head, but this is me fitting some more glass to the seat.

I put 2 more layers of glass on. Apparently my brush wasn't completely clean of VC17m.. it added some "color" to my resin (ugh)... I'll take a look once it's dry to see if it'll be OK... I'm going to gelcoat over all this so it might be alright. Hard to see but the layers are up to the gelcoat now, I'll be recoating that whole seat I think... so I'll be sanding the whole seat smooth. The dip for the traveler seems to have really taken shape, had to add several layers extra of pieces of glass, but it all seems to have sorted.

Yeah it all looks pretty messy but It'll all clean off I am sure.

Here's present state of wiring for the tiller pilot, along with a 12V aux port. My "plan" is to use the 12V aux port to plug a solar panel into.. backfeeding through a fuse to the battery directly. Yeah I have tons of connections to make (had to get more wire today).. will complete all the wiring then look at tidying it all up.

Mr. Fuzzycam reared it's head, but this is me fitting some more glass to the seat.

I put 2 more layers of glass on. Apparently my brush wasn't completely clean of VC17m.. it added some "color" to my resin (ugh)... I'll take a look once it's dry to see if it'll be OK... I'm going to gelcoat over all this so it might be alright. Hard to see but the layers are up to the gelcoat now, I'll be recoating that whole seat I think... so I'll be sanding the whole seat smooth. The dip for the traveler seems to have really taken shape, had to add several layers extra of pieces of glass, but it all seems to have sorted.

Yeah it all looks pretty messy but It'll all clean off I am sure.

Here's present state of wiring for the tiller pilot, along with a 12V aux port. My "plan" is to use the 12V aux port to plug a solar panel into.. backfeeding through a fuse to the battery directly. Yeah I have tons of connections to make (had to get more wire today).. will complete all the wiring then look at tidying it all up.

Presently hull 399, "Ragtime" Blackwater Yacht Racing, Smith Mountain Lake, VA

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Fomerly hull 68,"Rum Line," Paupack Sail Club, Lake Wallenpaupack, PA.

Re: Rambling repair post...

Uphill,

Replacement spreaders are available via the Class. Contact Paul Latour (secretary).

Thanks,

Replacement spreaders are available via the Class. Contact Paul Latour (secretary).

Thanks,

Re: Rambling repair post...

Uphill,

we are also installing a tiller pilot soon. our plans are to have it on the seat using a drop-down bracket.

thanks

we are also installing a tiller pilot soon. our plans are to have it on the seat using a drop-down bracket.

thanks